During winter, swine facilities usually operate at minimum-ventilation rates. But if those rates aren’t correct, high humidity and excess gases will build up leading to increased disease and reduced growth rates, reported Sam Holst, DVM, Swine Vet Center, St. Peter, Minnesota.

“A good understanding of basic ventilation concepts and some routine monitoring to make sure everything is working properly will help set up a barn environment to optimize health and performance while also keeping utility costs in check,” he said. “A lot of ventilation mistakes result from efforts to try to save propane or other utility costs.”

Holst offered several tactics to avoid common winter ventilation mistakes that increase costs.

Calculate minimum ventilation

A big mistake that increases costs and reduces pig performance is an incorrect minimum-ventilation rate.

“Minimum ventilation is the amount of fresh air needed to be brought into the barn to help control humidity and gases like carbon dioxide and ammonia,” Holst explained.

“It’s important to get this correct because over-ventilating will waste propane and electricity leading to inflated utility costs,” he said. “On the flip side, if we under-ventilate, we’ll produce an environment that’s detrimental to health and performance.”

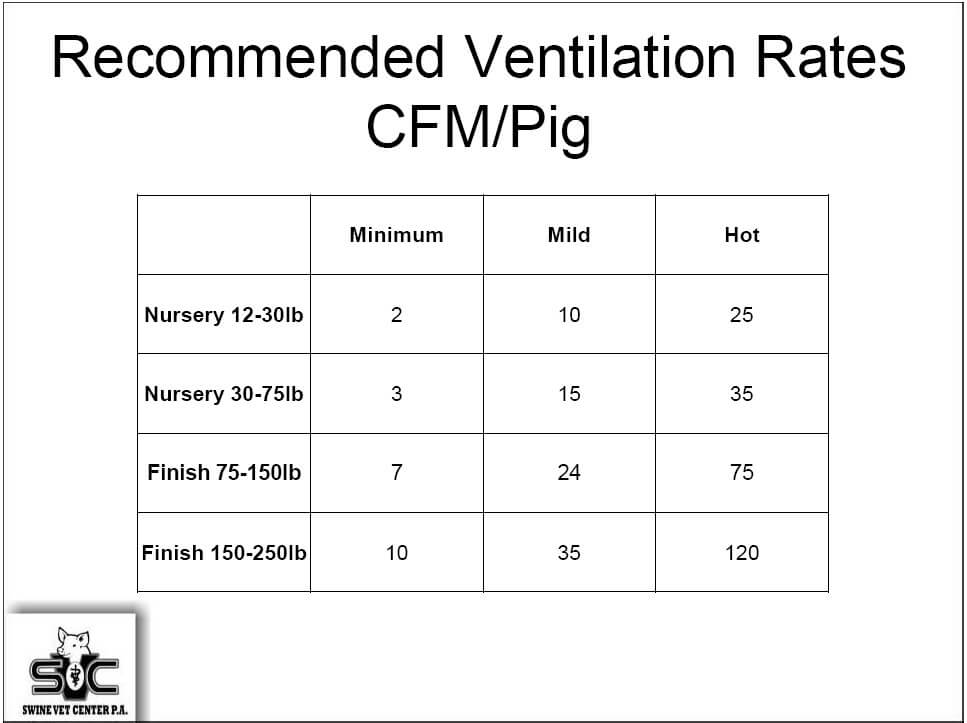

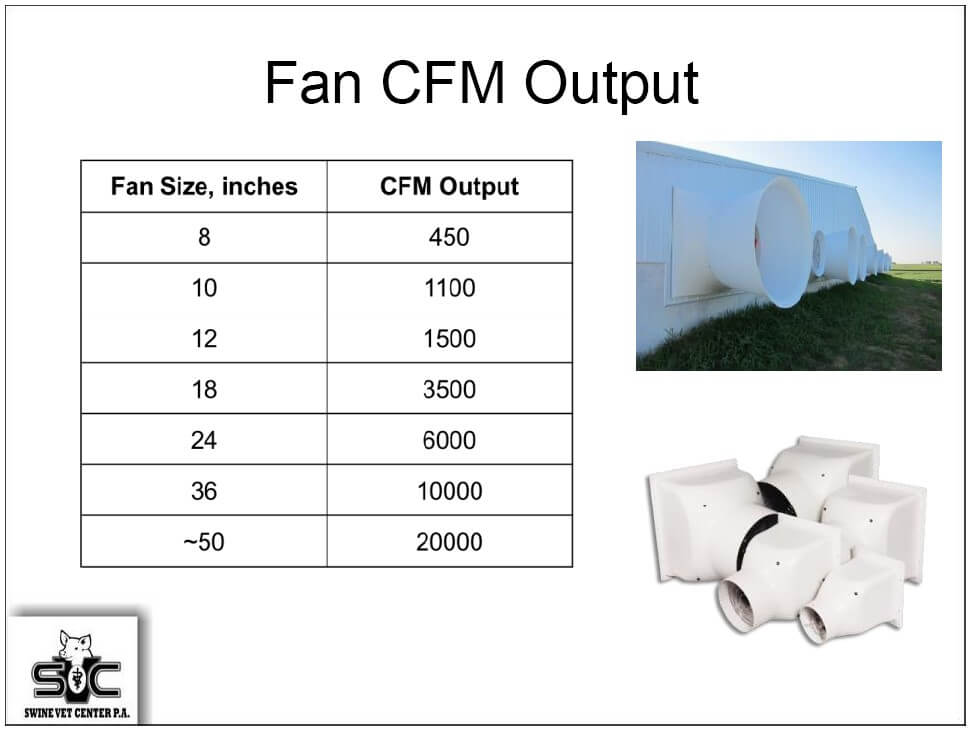

Minimum-ventilation rates should be calculated based on the number of pigs in the room and size of the fans on stage one. Use the following reference charts to help determine the minimum rates. Reference charts for required maximum cubic feet per minute (CFM) per pig and fan CFM output (Figure 1) and (Figure 2) are helpful for these calculations. (Located at end of article.)

“It’s worth the time and effort to calculate the minimum-speed setting for stage one rather than use an arbitrary setting,” Holst added.

Set heater correctly

During the winter, heater and furnace use increase greatly. Holst stressed making sure the heater is set correctly to achieve consistent room temperature and limit propane waste. He’s seen propane use drop by several gallons per heater per day when settings were corrected.

One costly mistake is setting the heater shutoff temperature too close to the set-point temperature. Room temperature rises even after the furnace shuts off as it takes some time for the heated air to circulate and the probes in the building to detect the increase in room temperature. If the heater is programmed to shut off too close to set point, the room temperature will rise above the set point causing minimum-ventilation fans to speed up and exhaust heated air – essentially blowing recently burned propane right out of the building.

“A good way to finetune furnace settings is to make note of the current settings and watch the room temperature as it cycles through a heater on-and-off run,” Holst explained. “Ideally, once the heater shuts off, the room temperature should rise to just below set point without going over. If the temperature rises above set point, then adjust the heater setting so it shuts off further below set point. In most cases this will be 1.5˚F to 2.0˚F below set point.”

Check temperature probes, fans

All the temperature data fed into the controller to determine ventilation settings comes from temperature probes located in the facilities. If the probes are not functioning correctly, are placed in incorrect locations or are at the wrong heights, information fed into the controller is inaccurate.

“If that happens, the result is an unfavorable barn environment,” Holst said.

Also, make sure fans are clean and not covered with debris and dust. Just 1/8 inch of dust will reduce fan efficiency by 40%, he added.

Wrap curtains in plastic

“It can be beneficial to cover curtains with bubble wrap or plastic in the winter to help reduce drafts and heat loss,” Holst said.

His recommendation is to fully cover curtains on the north side of buildings with bubble wrap or plastic. On the south side, cover the curtains up to one foot from where it opens at the top so the curtains can be opened during a warm day.

Following these recommendations for winter ventilation should help keep utility costs in check and provide a healthy environment for pig growth through cold weather, he added.

Figure 1.

Figure 2.