Biosecurity is a word we hear often in swine production but what does it truly mean? When I think about an how to explain this topic to a feed mill, I tend to use the following: Biosecurity is a means to create practical and science-based methods to reduce the likelihood of viruses and bacteria entering our production system.

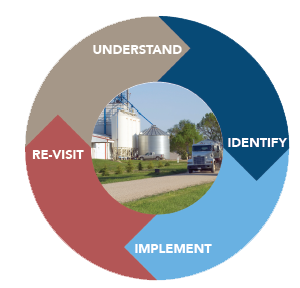

Historically, biosecurity has started at the farm level by showering in and out of facilities, danish entries, filtering facilities, disinfection protocols, and quarantine for incoming gilts. However, when thinking of the next level of biosecurity, feed rises to the top of the list as it is the next largest quantity product entering into the farm. Biosecurity continues to be a tough task at the feed mill as they are made up of complex networks of people, processes, and ingredients. Therefore, it becomes critical for feed mills to follow the continuous cycle of understanding, identifying, implementing, and revisiting.

Understand the Risk of Feed

Since the introduction of porcine epidemic diarrhea virus (PED) to the United States, a large amount of research has been conducted around the true risk that feed carries in our production systems. This includes ingredients, process, equipment, and personnel. Each mill is very different, but the processes and risk are generally very similar. Even though feed may not be the primary route of transmission, and in general is relatively small, the magnitude of infection can be extreme and cause a large economic loss to a farm or system.

Identifying Risk Factors Using Audits & Science

The best way to identify areas of concern in either an owned mill or toll mill is to first identify any potential areas a contaminate can enter the production system. This can be completed by creating a flow diagram for the feed mill listing out each process and movements of people and trucks. In general, the major area of concern includes ingredients, trucks, and people. However, in some systems there could be additional areas of concern such as livestock close by or on-site. Our strategy to identify risk factors has been to create an audit form using the most recent scientific research that not only scores a feed mill but will also help the mill better understand where the major risk areas within a feed mill can originate. This approach allows for conversation and brainstorming to figure out what procedures can be put in place that are not only successful but practical for the mill employees.

Implement Strategies

The number one question that gets asked regarding the implementation of a procedure or product is will it be practical? Two of the most practical and successful techniques that we have utilized in the feed industry are truck washing and the use of feed mitigants.

- Prevention Strategy -Truck sanitation is one of the most vital procedures to ensure a bio-secure feed delivery. In most instances this is completed with a pump sprayer using sanitizer and only includes the tires and undercarriage. What we have learned from research over the past few years is that the cab of the truck is becoming a very vital part of the sanitation process. Using sanitizers that are used on the tires of the trucks or in foot baths can also be used in the cabs and on the floor mats of the trucks. Both methods of washing the outside of the trucks and sanitizing the cabs are very practical and can be completed at the end of the feed delivery route or after visiting a site of concern. Not only does this protect the farms but it also protects drivers from carrying a potential contaminant back to the mill. This process can also be carried out on ingredient trucks entering a facility.

- Feed Mitigation -The second approach is the use of products that contain acids, alkalis, essential oils, medium chain fatty acids, and formalin are residual mitigation tools. These products can provide a lasting effect on the feed in which it can keep the product free of pathogens after the feed is treated. This reduces the risk of ingredients that could be contaminated and post processing contamination/ recontamination.

Over the past few years various products have been tested among many viruses and bacteria which makes it very important and difficult to find the correct type of product that is effective against the pathogen of concern. For example a study published in 2020 evaluated 19 products against PEDV, PRRS, and SVA in feed. The outcome provides readers with various options/types of products that can be used to target 1, 2, or all 3 of the viruses. If you have any questions regarding feed mitigation products or using a feed mitigant, please reach out to a member of Pipestone Nutrition or your veterinarian.

Revisit

After implementation it is important to revisit the procedures to make sure they are effective and working properly for the system. In some cases, you will have to change or adapt the procedures or audits to work in a specific system as each mill is different. Biosecurity will always be challenging and changing as more data becomes available and new technology is introduced.

Each year we continue to use this data to strengthen not only our production system but to help other feed mills strengthen their biosecurity plans. No matter the process or pathogen of concern we always continue to use the continuous cycle of biosecurity, which is to understand, identify, implement, and revisit using a practical and scientific approach.