Jeff Odle

LANXESS Corporation, Actives and Disinfectants, Pittsburgh, PA

Introduction

The swine industry in the United States was poised to have an excellent 2020 with new trade agreements in place with China, Japan, Korea, Mexico and Canada. Unfortunately, the COVID 19 pandemic hit the U.S.A. and swine producers struggled to survive, literally and financially. Pathogenic challenges did not go away for the animals and in fact biosecurity became even more important to workers, for their own personal safety. Some organizations look at cleaning and disinfection (C&D) as added expense but it can be an opportunity to save money and contribute to the bottom line.

Purchasing a C&D product that does not deliver, whether it be superior soil removal for a detergent or lack of efficacy against the intended pathogens for a disinfectant, is a waste of money. This paper will look at the cost benefit of an effective C&D program.

Start With a Detergent

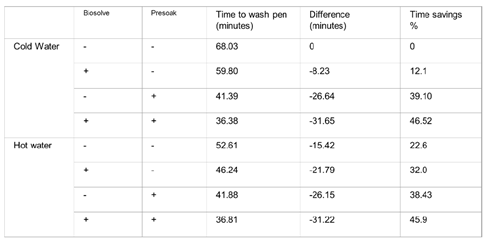

Even though formulated detergents add cost, the overall return on investment can be profound. Cleaning not only prepares the surface for disinfection but also decreases the number of pathogens by physically removing them. It is obviously easier for an antimicrobial to be effective when there are fewer microorganisms present. Organic matter, such as dried on feces, hard water scale, and biofilms all provide a protective barrier, which prevent the disinfectant from coming into contact with the pathogen. Biofilm also reacts with the disinfectant thus reducing concentration of available antimicrobial agent. Bacteria within a biofilm are 1,000 times more resistant to antimicrobials than bacteria in suspension. A study1 conducted by the University of Prince Edward Island, shows presoaking the surface reduced the amount of time needed for cleaning over no presoaking. Presoaking followed by a commercial detergent achieved a 46% reduction in the time required to clean each pen (Table 1).

Table 1. Average wash time per pen with varied washing protocols (Hurnik, 2005)

One could argue, cleaning is actually more beneficial than disinfecting by reducing the population of microorganisms by 80-90%. It is not chemically possible to open biofilms by power washing with water alone. Detergents lower the surface tension from 72 dynes per centimeter to 30 dynes per centimeter making soils easier to remove. Organic soils are better removed by using alkaline cleaners whereas hard water scale responds more favorably to acidic pH cleaners. Foaming cleaners allow longer contact time, especially on vertical surfaces, for penetration and removal of soils.

This same study also evaluated the impact on animal productivity by tracking days to market with a target finish weight of 110kg (243lbs). Pens where a presoak was followed by a commercial detergent and a peroxygen disinfectant resulted in a 5.2% reduction in number of days to market.

Time Is Money is an aphorism attributed to Benjamin Franklin. In this case, time saved equals less cost in labor, less power and water used, reduced downtime and improved feed to gain productivity.

Cost In-use

Disinfectants are used at varying concentrations and come in many different size containers. It is important to calculate cost in-use in order to get an accurate comparison. Most liquid disinfectants are used at a 1:256 dilution rate meaning a 1 gallon jug of concentrate will dilute to 256 gallons in-use. Price divided by number of gallons equals cost in-use. Powder based products, such as Virkon™ S, are used at a 1:100 or 1:600 concentration. Therefore a 10lb. pail of powder concentrate at 1:100 will make 123 gallons and at 1:600 a total of 738 gallons of in- use solution. If larger volume containers are available, these are generally sold at even lower cost per pound or gallon resulting in additional savings.

A disinfectant must be effective against the pathogens of concern otherwise it is wasted money and effort. Does the disinfectant have the proper label claims proving efficacy? Does it work under the environmental conditions in which it is being used, such as cold temperatures in winter or fast contact times for boot baths?

Most disinfectants are used at a single label recommended concentration for a broad spectrum kill of the listed pathogens on the label. Where lower concentrations are specified for known and specific diseases, it allows the end user to tailor their use to the application. Broad spectrum kill is important where the most susceptible animals are present or where a disease challenge has been identified. In applications like transportation, viral transfer of PRRS and PEDv from farm to farm is the greatest concern. If lower disinfectant concentrations proving efficacy against known pathogens, like PRRS and PEDv, are listed on the label, then there is an opportunity to significantly reduce cost in-use for certain applications.

Conclusion

Providing animals a clean and healthy environment, allows them to grow and thrive at their utmost potential. Good biosecurity starts with cleaning. The standard use dilution test used for testing disinfectant efficacy calls for only 5% organic challenge. Cleaning reduces the number of pathogens present and prepares the surface for an effective disinfection. Understanding the importance of cleaning, calculating cost in-use, and using a proven disinfectant chemistry which provides efficacy over a wide range of conditions and applications will allow for enhanced biosecurity and cost savings. The return on investment will be measured in healthier animals with greater productivity, less therapeutic costs and lower mortality.

References

- Hurnik, D. 2005. Investigations into optimal washing and disinfection techniques for pig pens. London Swine Conference – Production at the Leading Edge 6-7