Dylan Lape, DVM

Pork Veterinary Solutions

June 6, 2021

Introduction:

In livestock production, it is the job of the veterinarian to help and, advise producers on

how best to keep their animals healthy throughout the production cycle. In particular, in swine production we see a lot of focus on keeping diseases out of a production unit, mainly at the sow farm level, but as we observed this past winter even our best efforts sometimes fail. So, in order to grow as both veterinarians and producers we must ask ourselves what went wrong, and how can we prevent it from happening again in the future?

Risk Events:

When we take a look at every day normal swine production practices, we can determine that there are multiple opportunities for risk events to occur. These risk events are generally accepted because they are necessary for the day-to-day operation of the farm. Whether that be entry of staff and visitors, supplies, vehicles, semen, gilts, etc. or livestock leaving as cull sows or wean pigs. Therefore, in order to address each of these potential risk events we develop and implement an integrated set of biosecurity protocols. So, if we are implementing a robust set of biosecurity protocols, how do we end up with so many disease outbreaks? That is the million-dollar question!

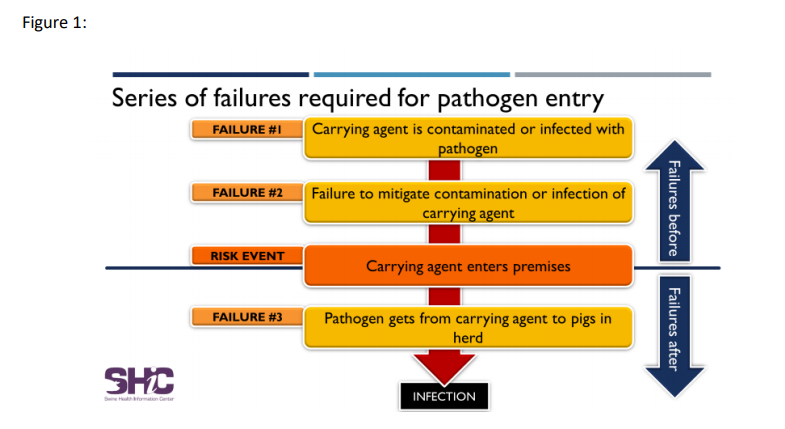

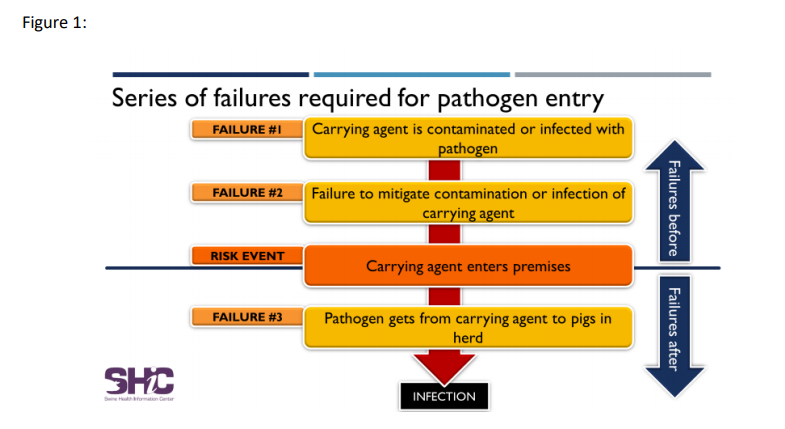

First, we must realize as Dr. Derald Holtkamp described in his 2020 Leman conference presentation, disease outbreak is attributed to a series of failures that occur around a specific risk event. (Figure 1.) First, the carrying agent is contaminated or infected with the pathogen, second there is a failure to mitigate the contamination or infection of the carrying agent and third after the infected carrying agent enters the farm it is introduced to the pigs in the herd.

Often, after we have evaluated and determined where these failures to prevent disease from entering a production unit have occurred, we rush to implement new protocols, or we pick up on protocols that may have become less diligent and reimplement them correctly. However, as time passes and the disease outbreak fades from our memory, we become complacent and tend to start pulling these extra biosecurity measures we implemented, usually starting with the most expensive, or most time consuming. As an industry we are very reactionary to threats of disease, but reactionary does not always work out. The more diligent we can remain even when the threat of disease is lower, the more likely we are to prevent outbreaks from occurring in the first place.

Prevention of Further Disease Outbreaks:

In the event of a disease outbreak, often the highest priority quickly becomes to prevent further outbreaks from occurring within other areas of the system. We can do this through a multitude of steps, with the following being considered the most important: Cleaning and Disinfecting, Thorough Testing Protocols, and People.

We are finding more and more that a break down in the implementation of effective biosecurity cleaning and disinfecting protocols for swine transportation trucks and the farm buildings themselves, is leading to increased instances of disease. Truck washing is a hot topic within the industry, as many companies and producers have varying procedures for cleaning and disinfecting them, especially when it comes to those that travel to market. Some pig market trucks are only being washed every 4th or 5th load! Imagine, after 5 loads of pigs that truck is now potentially a potent source of infection for diseases

such as PRRS and PEDv. It then goes through a commercial washing unit where water blasts organic matter from the surfaces of the vehicles onto the ground and, your weaning truck is next in line to go through the wash. The potential for you to contaminate your vehicle and bring these diseases back to your sow farm is now increased. Short of constructing your own internal truck wash, the potential for cross contamination is sometimes an inevitable risk; however, you can implement one further step to

mitigate that risk. If you bring the trucks back to a separate location and complete a second disinfection with a quality disinfectant such as Virkon™ S, you can help decrease the likelihood of disease being transferred and causing an outbreak on your farm.

Thorough testing protocols are also important! I highly recommend clients to, at the very least monitor gilts coming into their herds! Even with my clients that are internally multiplying I recommend they test oral fluids for PRRS, Flu, and the Coronavirus Panel. This can be a fail-safe if you have exposure in a finisher with Gilts or happen to have an exposure event at your GDU, it will help keep you from blowing up the entire sow unit. Often, I see this implemented right after an outbreak, but it seems to be one of the first things dropped as a way to cut costs.

People and their actions are one of the hardest things to regulate, but it can be done. You might say, “well everyone showers in/ and showers out, and follows all of our biosecurity procedures”, but naturally as humans we are always looking for the easiest way to do things. And occasionally that can come back to bite us. For example, employee John at your Sow Farm, was running late today, he showered at home this morning, so when he got to the farm, he skipped his in shower. Little did he know that on his way to work when he stopped at the gas station, he interacted with Truck Driver Joe who was hauling a load of PRRS positive pigs. Employee John potentially now just brought PRRS into your sow farm. It is important that we develop an understanding amongst employees that these

protocols are of utmost importance, and they should always take the time to follow procedures.

Conclusion:

In conclusion, I believe within the industry we have the ability to push a focus on these costly diseases that continue to plague us with outbreaks every year, and potentially prevent many of them from occurring. A collaborative effort is needed, and we need to focus on more stringent biosecurity cleaning and disinfection procedures, especially related to swine transportation. The biggest push back I hear is, “well what is that going to cost me?”, but the important thing to think about is, what will a PRRS or PEDv outbreak cost me? We know annually PRRS outbreaks cost the swine industry 664+ million dollars a year in the U.S. alone! (Holtkamp et. al., 2013) There is a world of opportunity, and I believe it starts with spending more time on prevention of disease outbreaks through the steps as outlined above!