Introduction

Housing sows in individual stalls has become commonplace across the pork industry. This method of production has grown in popularity because animals can be housed and cared for individually. However, growing consumer concern has increased scrutiny on this standard industry practice. Multiple states have passed legislation that mandates that pregnant females be group housed for specified portions of gestation. This change in system design and production method has caused concerns among producers, who have stated their need for information and specifications on group sow housing options. In Michigan, results from pork producer focus groups identified descriptions and cost comparisons of group housing methods as their top educational need. This bulletin describes using short stalls, sometimes called non-gated stalls or stanchions, and trickle feeding for group housing gestating sows.

General description of system

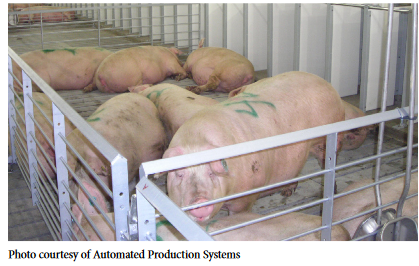

One option for group sow housing is to house sows in pens with non-gated feeding stalls, often called short stalls or stanchions. These short stalls are typically open gate dividers with a feed drop at each feeding space. Short stalls and trickle feeding systems are competitive feeding systems, but by dividing the feed area, the feeding stall provides a small measure of protection for the sow while feeding.

A typical short-stall facility can house animals in small groups of four to six animals, but facility design can allow for larger pens of 20 or more sows. The feeding system is a standard drop feed design – for each feeding space in the pen, a feed box is attached to a drop feed tube that will drop feed onto the concrete floor, into a feed pan or into a trough. Producers can drop all of the sow’s feed at one time or split the daily feed allotment into multiple drops or meals each day. Producers can also opt to use a trickle system, which releases small amounts of feed continuously over a defined period of time to “fix” the sows in place while they eat their feed. Water can be supplied in the feed trough if a trough is used, or with nipple drinkers attached to gating. The floor can be completely slatted or partially slatted with solid concrete in the feeding area.

For both short stalls and trickle feeding, the divider between feeding spaces allows for the sow’s head to be protected while she is eating. Dominant sows can still be aggressive toward their pen mates during feeding times after they have consumed their own feed allotment. The stalls will vary in length according to the recommendation of the manufacturer. Typical lengths are 18, 24 or 36 inches, which are sometimes referred to as head length (18 inches) or shoulder length (24 to 36 inches). On some farms, using an 18-inch or head-length short stall has been associated with detrimental management and behavior issues for sows in those pens. Some companies have suggested that the 24- or 36-inch divider should be used instead.

Trickle feed system

A trickle feed system has a similar configuration to a short-stall system but it has more augers to deliver and drop the feed. Often one auger will move the feed into a feed box and a second will drop the feed from the box into the feed pan or trough at a slower, “trickle” rate. The sows are kept in place by the trickling feed, which should be dispensed at a rate that the slowest eating sow can consume (Levis & Conner, 2013). This keeps any one sow from quickly consuming her feed allocation and then moving on to another sow’s allotment. The trickle auger typically dispenses feed at a rate of 0.17 to 0.44 pound per minute, and feeding times last 15 to 30 minutes. Producers may opt to use a trickle feed system, instead of a short-stall system, to decrease the competition for food in small-pen systems (Levis & Conner, 2013). The addition of another auger system may also require more maintenance and upkeep for the facility in general.

Group size and makeup

Short stalls and trickle feeding are typically used in a small-pen setting with fewer than 10 sows per pen. These are considered competitive feeding systems, and the more aggressive or “boss” sow(s) in each pen may have a negative influence on subordinate sows that they are housed with. This could create body condition score (BCS) issues, along with multiple injuries due to fighting within the pen.

Floor space allocation in competitive feeding systems is a critical consideration. Bigger and older sows should be provided more space than smaller and younger animals. Floor space allocation should be 15 to 18 square feet per animal for gilts, 19 to 24 square feet for mature sows, and 18 to 23 square feet for a mixture of gilts and sows (Gonyou, Rioja-Lang, & Seddon, 2013). Managing the floor space allocation in a competitive and small-pen system is key to having an effective and efficient group-housed facility.

The space in small pens is completely shared space. This type of pen design does not allow for loafing space or areas where the subordinate animals can hide from the dominant ones. To reduce potential aggression, it is important to create pens of sows that are similar in size, parity and BCS. Penning sows of similar size and age together should also reduce size variability and allow for similar feed allotments for each animal in the pen. This should improve the employees’ ability to manage the nutritional needs of the sows and maintain appropriate BCS of the sows within a pen.

Static versus dynamic groups

Group-housed gestating females are penned into static groups or dynamic groups. Static groups are groups of females that are mixed once, and no new animals are added to the pen after the group is formed. Sows that become open or injured may be removed, but no new animals are added into the pen. Dynamic groups are those in which females are regularly added to pens with females already in them. Static groups are typically small groups with no more than 20 sows in a pen; dynamic groups are typically larger groups with more than 40 animals in the pen, and they can be as large as several hundred.

Group housing systems with small pens are typically managed using static groups. The number of feeding spaces in the pen should be equal to the number of females placed in the pen. With competitive feeding systems such as short stalls or trickle feeding, there should never be more sows placed into the pen than there are feeding spaces. If a sow is removed from the pen, there will be more floor space per sow in the pen than in pens that have maintained their original grouping. This is sometimes thought of as being an inefficient use of space. However, placing one or two sows into a resident group of sows will cause aggressiveness and fighting, and the newly placed sows could be become injured and subsequently need to be removed. Therefore, placing new sows into an established pen is not recommended and, in fact, highly discouraged when using competitive feeding systems such as short stalls or trickle feeding.

Management ofreplacement gilts

Managing replacement gilts in a group sow housing system is a critical component for maintaining a high-performing sow herd. Because gilts are smaller than older sows, they do not need as much floor space and can be housed at 15 to 18 square feet per animal without experiencing detrimental effects on performance (Gonyou, Rioja-Lang, & Seddon, 2013). A pen that will house four to five fully grown sows typically may hold approximately six gilts. A feed drop should be in place for each animal housed in the pen.

When forming breeding groups with gilts, gilts should be mixed only with other gilts and possibly with younger parity sows. This allows for the most efficient use of space in a small-pen system and may decrease the amount of competition between animals. It also groups animals with similar nutritional needs.

Equipment and technology needs

Using short stalls or trickle feeding limits the use of technology that could be incorporated into a feeding system. This option may be attractive to those who manage their farms without the use of a computerized record-keeping system or do not have employees with the skills to use and manage computer systems. The repairs and updates needed for short-stall and trickle feeding systems should not be much different from those of traditional gestation stalls.

System specifics

Typical pen design

Typically, the pens for short stalls and trickle feeding are rectangular rather than square. This will be advantageous when remodeling traditional conventional stalled buildings because some of the current stalls and feed lines can be utilized in the retrofit, possibly reducing the initial remodeling costs. It should be understood, however, that remodeling a stalled gestation barn and implementing group sow housing with short stalls or trickle feeding will mean that sows will have more floor space allocated to them than they would have in stall barns. In many cases, this will decrease the number of sows that can be housed within the existing building shell.

Decreasing aggressiveness using multiple feedings

It has been suggested that sows housed in competitive feeding systems such as short stalls and trickle feeding should be fed multiple times per day. Feeding sows two or three times per day has been reported to decrease aggressive behavior, which should result in less fighting and fewer injuries. It has been also been suggested but not extensively substantiated that adding fiber to the diet can also reduce aggressive behavior because sows feel less hungry throughout the day (DeRouchey & Tokach, 2013).

Management of BCS and lame or injured animals

With group housing systems that house sows in small pens, employees will have to develop means to properly manage BCS and observation protocols for sows housed in groups. Managing BCS will be directly linked to initially penning sows of similar size and BCS and feeding them accordingly. Observation protocols must be developed to identify females that may be becoming lame or that have been injured so that treatment can begin early in the onset of the condition. Ideally, sows should be treated within their pen groups and remain in their pen groups during the course of their treatment. If a female must be removed from the pen, she should be moved to an area where she can recover without further aggressiveness from other sows. Compromised sows could be moved to individual stalls used to treat sows or small pens to house individual sows. Producers should provide employee training that will improve employees’ ability to identify sows soon after they become injured and to provide aggressive medical care and treatment so as to keep sows in their pen groups and minimize the number of sows that have to be housed individually because of condition, illness or injury.

Labor needs and requirements

As farms transition from gestation stalls to group sow housing, employees must be trained appropriately to develop their observational skills and use them differently than before. Traditionally, swine farms hire and train employees to become task-oriented – to focus on completing single tasks throughout the work day. When working with sows housed in groups, employees need to be able to focus on multiple tasks at one time and be aware of what is happening in the barn as a whole, as well as in each pen. Improving employee observational skills is a challenging task, but, once accomplished, it will improve the overall efficiencies on the farm.

The daily work routine will differ with the type of group housing system used. Production staff members and farm managers should develop a workable outline that highlights the important areas to be evaluated each day. Over time, this may be updated and changed to accommodate the particular nuances experienced on the farm. Employees working in small-pen systems will have to develop methods that allow them to thoroughly observe the group housed sows as individuals. Good management of a small-pen system often hinges on the caretakers’ ability to find animals that may be lame or injured and provide them with proper care in their resident pen. Although employee numbers on the farm are not expected to change, the daily tasks and routines will have to be adjusted when managing a group sow housing system. Producers may also need to change their focus when hiring. New hires should be able to adapt to working with animals in groups and be able to multitask.

Advantages and disadvantages

All group housing systems have advantages and disadvantages, those for short stall and trickle feeding systems follow.

Advantages

»Limited moving and computerized parts – short stalls and trickle feeding systems have limited parts that may need replacement compared with systems with more technology or moving parts, so they have potentially lower upkeep costs. For the most part, much of the equipment will be similar to that used in stalled gestation barns.

»Group feeding – all sows are fed at the same time, resulting in decreased aggression at the start of the feeding period.

»Small groups may mean better and easier observation of individuals – because all of the animals are up and eating at the same time, employees may find it easy to observe animals for lameness or injury.

»Retrofit capabilities – use of short stalls or trickle feeding can allow for a straightforward remodel from a traditional stall layout. The original feed lines and some stalls can be incorporated into the updated design, thus decreasing the cost of the new group housing system.

Disadvantages

»Competitive system – short stalls and trickle feeding are competitive feeding systems that provide a minimal amount of protection while animals are eating and do not allow for subordinate sows to hide from dominant sows.

»Feed wastage – there is potential for feed wastage in this type of a system, especially if the pen design has a completely slatted floor.

»Less efficient use of square footage – short stalls and trickle feeding systems should be managed as static groups. Removing animals from the group reduces the efficiency of the space usage of each pen.

»Lack of individual feeding opportunities – all the animals in the pen are fed at the same time and can access any feed drop that is available. This does not allow for controlling the amount of feed that each sow gets and can increase BCS differences within pens of sows.

Conclusion

Small pens with short stalls are a viable option for group sow housing. This type of group housing system allows for sows to be managed and observed in small groups. It also allows for the retrofit of traditional complete stall buildings, therefore potentially decreasing the initial cost of implementing group sow housing compared with more expensive options. The maintenance and labor needs and expectations remain similar to those of a traditional stall building, with more emphasis on observation and treatment of the animals in their originally formed gestation groups or pens. Farms considering small-pen short-stall systems, with or without trickle feeding, should determine the number of pens that would be needed, feed system design and the flow of animals through the system. When assessing this type of system, producers should evaluate system costs and the need for new skills among employees.

References

DeRouchey, J., & Tokach, M. (2013). Group housing systems: Nutritional considerations [fact sheet 03647-3/13]. Des Moines, IA: National Pork Board. Retrieved from www.pork.org/options-sow-housing

Gonyou, H., Rioja-Lang, F., & Seddon, Y. (2013). Group housing systems: Floor space allowance and group size [fact sheet 03645-3/13]. National Pork Board. Retrieved from www.pork.org/options-sow-housing

Levis, D. G., & Connor, L. (2013). Group sow housing systems: Choices and designs [fact sheet 03643-3/13]. Des Moines, IA: National Pork Board. Retrieved from www.pork.org/options-sow-housing

Acknowledgments

Authors:Beth Ferry Educator, MSU Extension

Roger BetzEducator, MSU Extension

Ronald O. BatesDirector, Agriculture and Agribusiness Institute,

MSU ExtensionFunding support by Michigan Pork Producers Association.Produced by ANR Communications (anrcom.msu.edu), and designed by Samantha Proud, student graphic designer, for MSU Extension (msue.anr.msu.edu).

Visit the Gestation Group Sow Housing page on the MSU Extension website at bit.ly/SowHousingOption