Introduction

It is important to keep young pigs warm to improve growth and survivability. At this stage of a pig’s life, their immune systems are still developing and their energy intake at weaning is limited. This reduces their ability to produce heat. The ideal air temperature for newly weaned pigs is 83°F, with an ideal flooring mat temperature of 95°F. The pigs’ required mat and air temperatures begin to decrease gradually seven days after placement.

Reducing environmental stress allows the young pigs to devote less energy to thermoregulation. Proper temperatures are critical during the post-weaning period to allow the pigs’ immune systems to become resilient to disease. Feed intake and feed conversion are affected by the temperature in the facility.

Although pigs produce body heat, small pigs often cannot produce enough warmth to maintain appropriate temperatures inside the pig facility. Many nursery or wean-finish facilities use supplemental heating sources to assure that the pigs are kept at the correct temperature. Some of the most common heating sources are forced air heaters, heat lamps, gas-fired brooders, and radiant tubes.

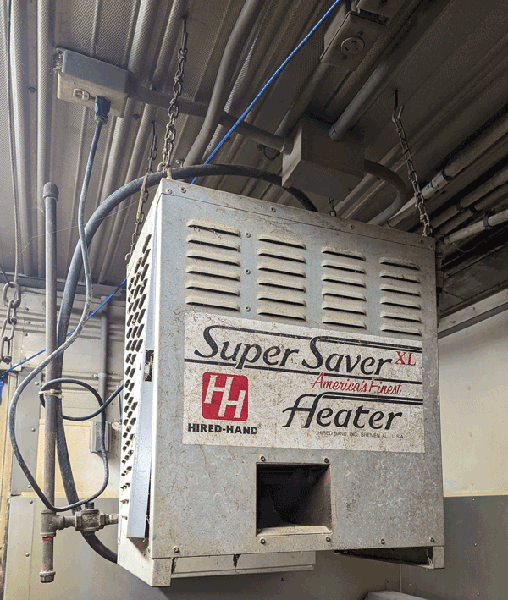

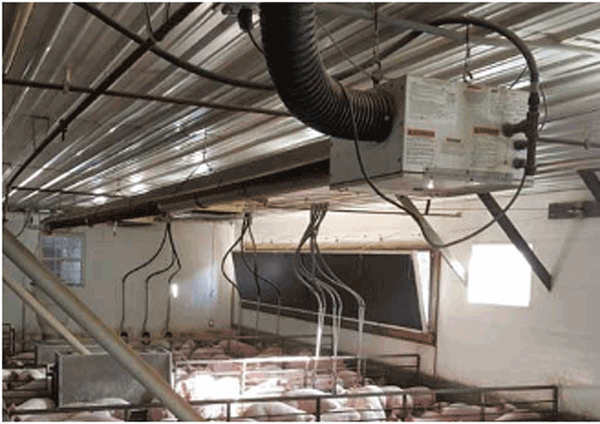

Forced Air Heater

Forced air heaters are units that heat the whole room to a desired setpoint temperature. Unlike heat lamps, radiant tubes, and gas-fired brooders, the air is heated first which in turn warms the pigs. The unit re-circulates room air, heats it, and then pushes the warmed air into the room. These heaters are commonly installed by hanging the units from the ceiling in a few locations around the room, depending on the room size and layout (Figure 1). The heaters can also be mounted on an exterior wall to use fresh outdoor air rather than re-circulated room air.

This heating source uses combustion and creates by-products such as water vapor, carbon dioxide, and carbon monoxide. Some forced air heaters are vented to allow gases and byproducts to be piped outside the building for release. However, many heaters are not vented, which means that these compounds are released directly into the room where the heater is operating. Improper maintenance or operation can potentially lead to build-up of combustion by-products within the room, particularly carbon monoxide.

Other disadvantages of using forced air heaters are the possibility of heated air loss through windows or cracks within the facility, and the need for more time to heat the floor surface compared to the other heating sources.

Heat Lamp

A heat lamp uses radiant energy to heat the floor and the pigs’ bodies directly instead of heating the air. The lamp is suspended 2 to 4 feet above the floor (Figure 2). The closer the lamp is to the floor, the higher the floor temperature but the smaller the heated area. The temperature is regulated by adjusting the hanging height of the lamp. The temperature must be adjusted as the pigs grow.

A variety of incandescent, infrared, and ceramic bulb options are available commercially. Common problems with the heat lamp are bulbs breaking when they get wet and frequently burning out.

Gas-fired Brooder

A brooder is similar to a heat lamp but is much larger and placed 4 to 5 feet above the floor (Figure 3). Brooders produce radiant heat to warm the surfaces and pigs. A brooder can be powered by natural gas or propane. The cover or shroud is usually made of stainless steel for easy cleaning to improve the life span.

Radiant Tube

A radiant tube also uses radiant heat to keep the pigs warm. The tube directly heats the surfaces and pigs without heating the air in the entire room. The tube is placed 6 feet above the floor and is typically suspended near the ceiling (Figure 4). The tubes, which can vary from 15 to 40 feet long, cover a larger heating area than heat lamps or brooders.

Tubes can be mounted at an angle to cover multiple pens at one time or can face directly downward on one pen. Typically, one radiant tube is mounted slightly off-center along the length of the barn to cover pens on both sides of the alleyway.

Summary

| Heat Source | |||||||

|---|---|---|---|---|---|---|---|

| Forced Air Heater | Heat Lamp | Gas-fired Brooder | Radiant Tube | ||||

| Fuel Source1 | LP | NG | Electricity | LP | NG | LP | NG |

| Fuel Usage | 2.8–5.3 lb/hr | 60–115

cu ft/hr |

100–250 W | 0.8–1.9

lb/hr |

17–40

cu ft/hr |

2.8–5.8 lb/hr | 60–125 cu ft/hr |

| Heat Output | 60k–225k BTU/hr | 340–850 BTU/hr

(100–250 W) |

10k–40k BTU/hr | 60k–220k BTU/hr | |||

| Purchase Cost | $$$ | $ | $$ | $$$ | |||

| Operating Cost | $$ | $$$ | $ | $ | |||

| Approximate Number of Pigs per Unit | 200–1000, depending on climate and facility | 6–8 | 20 | 100–500 | |||

| Positives | Widely available Long-lasting | Easy to reposition

Simple to use Widely available |

Versatile Sturdy | Even heat distribution

Coverage of very large area |

|||

| Negatives | Noisy

More heat loss to outside |

Sharp glass/ceramic pieces when bulbs break

Heats only small area Bulbs must be replaced often |

Surface very hot and can burn if touched

Can lead to excess carbon monoxide if improperly cleaned or dirty |

High purchase price

Limited ceiling height for mounting |

|||

| Average Life Span | 15–20 years | Bulbs: 6 months Shrouds: 5–7 years | 2–5 years | 5–15 years | |||

1 LP – Liquid Propane; NG – Natural Gas ↵

Regardless of heat source, post-weaning pig behaviors and postures can tell you if your pigs are at the appropriate temperature. If pigs are huddled very tightly and lying on top of one another, you can assume the pigs are cold. Pigs that are lying side-by-side are usually at a comfortable temperature. Pigs that are separated and trying to stay away from each other are usually a good indicator that the temperature is too high.

Placing post-weaning pigs in proper environmental conditions is critical for pig success. The barn should be kept clean, dry, and free of air drafts with a ventilation rate of at least 2 cubic feet per minute (CFM) per pig at placement and no more than 65% relative humidity. Regardless of heating source, it is recommended to provide about 0.4 square feet of heated area per pig. Pre-heating the facility prior to pig arrival is needed to achieve these conditions, especially with concrete slats or in colder climates.