How a clean living environment contributes to the reduction of post-weaning diarrhea

Post-Weaning Diarrhoea (PWD) affects more than half (54%) of global pig farmers at an average cost of more than $7/pig. The biggest impact on piglet performance is the reduced growth rate, with factors such as: longer to finish, increased mortality, increased feed cost of 7-9%, and a predisposition to other health issues also being cited.

The post-weaning period is very critical for the health and technical performance of piglets due to the loss of maternal immunity, weaning-related stressors (including moving and mixing animals), and the abrupt transition to solid feed. Antibiotic use in pig farming is most abundant in the first weeks post-weaning and mostly aims to treat digestive and respiratory diseases.

How pigs get infected

Post-weaning diarrhea is commonly associated with the proliferation of enterotoxigenic Escherichia coli in the pig’s intestine.

Infection of e.coli starts with the ingestion (1) of the pathogen by the surrounding followed by colonization (2) in the jejunum and ileum of the small piglets. Destroyed intestinal villi will lead to a loss of water and electrolytes absorption (3) causing diarrhea, weight loss, and death (4).

A multifactorial approach against post-weaning diarrhea

- The prevention of post-weaning diarrhea can be achieved via a multifactorial approach. Feed management, climate control, vaccination programs & a germ-free living environment all contribute.

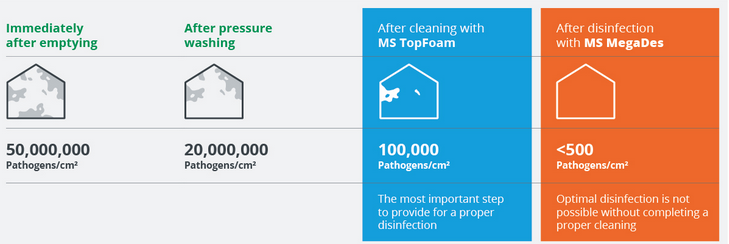

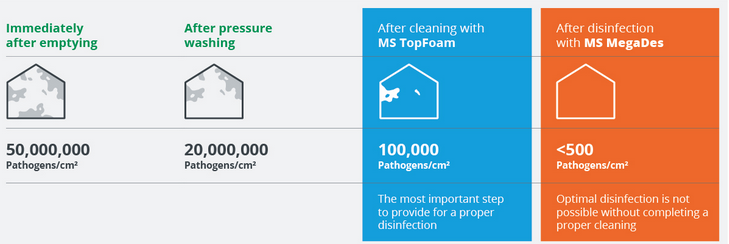

- An optimal hygienic environment is achieved by reducing the number of pathogens in the living environment of piglets to a minimum.

- With insufficient cleaning and disinfection between production rounds, pathogens or their spores can be left behind and the risk of infection remains present.

Hygiene management requires effective cleaning

A strict cleaning and disinfection program in between rounds makes sure that the new batch of pigs doesn’t get exposed to diseases from the previous ones.

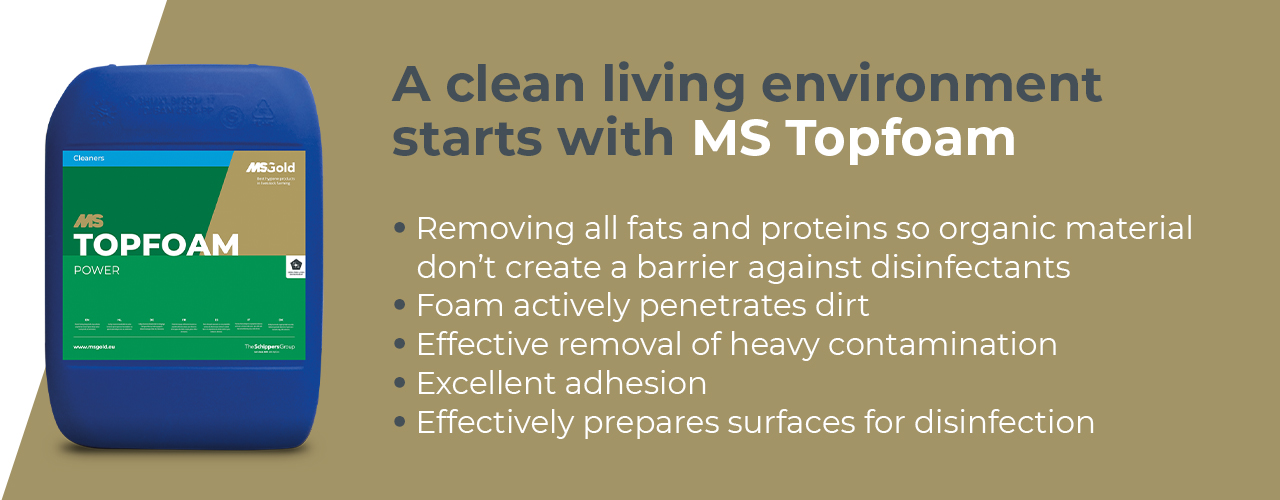

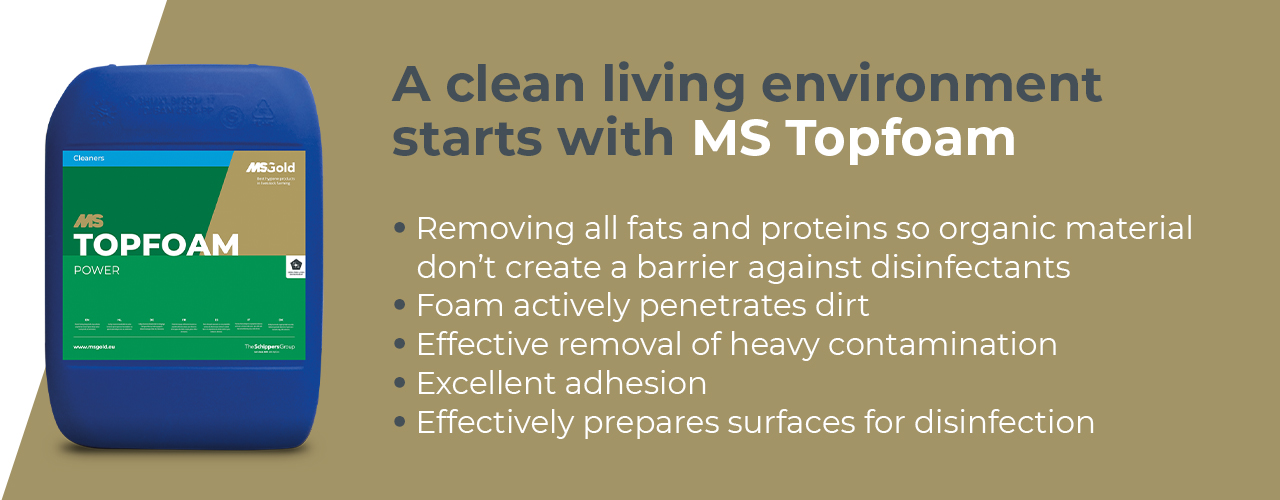

To make sure no organic material will interfere with the disinfection process, foam cleaning must be done prior to disinfection. Foam actively penetrates and breaks down contamination and reduces pathogen pressure.

For more information, or to schedule a consultation, reach out to Schippers Canada at 1-866-995-7771!